Sustainability

Sustainability Statement

SUSTAINABILITY STATEMENT FY2018

This Sustainability Statement covers our Group’s business operations in Malaysia for the financial year ended 30 November 2018 and has been prepared in accordance with the guidelines set out in the Main Market Listing Requirements in relation to the Sustainability Statement in Annual Report of Listed Issuers (“Guidelines”) issued by Bursa Malaysia Securities Berhad.

Our Vision 2040 is “To Enrich Wellbeing For The Community”. From our humble beginning in manufacturing metal rollforming products (in which metal is highly recyclable) to the processing of energy efficient safety glass products (contributing to green building), sustainable development has been integral to our business framework as we expand our presence region-wide and work towards a sustainable future.

As we have grown to become one of the leading metal roll-forming and safety glass processing manufacturers in Malaysia and Thailand, we have woven the concept of sustainable development into the fabric of our Group. By ensuring sustainable progress throughout our Group, we are providing the momentum for our businesses to strengthen operational efficiencies and deliver long-term growth.

Our sustainability framework is led from the top and the responsibilities played by each level of our organisation are shown in the following table:

| Board of Directors | Management | Operating Divisions |

|---|---|---|

|

|

|

Proactive stakeholder engagement ensures our business activities are viable, strategic and relevant. We engage with a diverse group of stakeholders as shown in the following table:

| Stakeholders | Key Focus Area | Method and Frequency |

|---|---|---|

| Shareholders |

|

|

| Clients / Customers, Suppliers and Industry Partners |

|

|

| Shareholders |

|

|

| Regulators and Government Authorities |

|

|

| Employees |

|

|

| Local community, Industry Associations, Academia and Non-Governmental Organisations (“ NGOs”) |

|

|

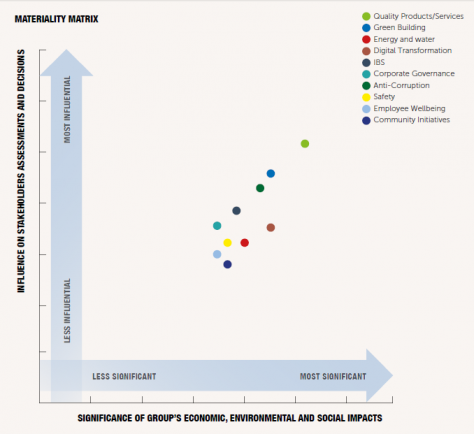

We carried out materiality assessment to identify and prioritise the economic, environment and social topics to drive our sustainability development. We adopted the following process for our material assessment:

Identification |

We identified material sustainability issues across our Group by convening the response from internal and external sources which were categorised into 12 distinctive themes as shown in the Materiality Matrix:Internal: Board of Directors, key senior management, head of departments and employees.

External: Clients/customers, suppliers, industry partners, regulators and government authorities, local communities, industry associations, academia as well as NGOs. |

Prioritisation |

When prioritising material sustainability issues, we take the following into account:

|

Internal Scope |

The scope of materiality only covers our Group’s business operations in metal roll-forming and safety glass processing in Malaysia for the financial year ended 30 November 2018. We do not cover our Group’s business operations in Thailand as the financial contribution from such business operations are not material. |

Review |

Govern by the Board of Directors, the Management Team reviews and oversees the planning and implementation of sustainability practices in a continuous and systematic manner.

Given that this is the Company’s first sustainability statement, focus has been placed on establishing the necessary framework. Moving forward, the Company will improve its implementation and monitoring process on sustainability initiatives. |

| Topic | Description |

|---|---|

| Corporate Governance |

|

| Anti-Corruption |

|

| IBS |

|

| Green Building |

|

| Quality Products / Services |

|

| Energy and Water |

|

| Community Initiatives |

|

| Employee Wellbeing |

|

| Digital Transformation |

|

| Employee Wellbeing |

|

| Safety |

|

The concept of materiality establishes the foundation of our sustainability actions and reporting. The matrix below presents the results of our materiality study. This guides us to report in line with the interests and needs of our stakeholders.

From the matrix above, we aspire to demonstrate our commitment to sustainability in the following areas:

(a) Marketplace;

(b) Environment;

(c) Community; and

(d) Workplace.

CORPORATE GOVERNANCE AND COMPLIANCE

We are guided by the Malaysian Code on Corporate Governance 2017 in ensuring the principles and best practices of good corporate governance is applied throughout our Group. Details of our corporate governance framework and practices are elaborated in the Corporate Governance Overview Statement of the Annual Report 2018 and the Corporate Governance Report 2018.

We have established effective standard operating policies and procedures, defined levels of authority and guidelines for recruitment and human capital development in our effort to ensure compliance with internal controls, laws and regulations. These policies, procedures and guidelines are subjected to regular reviews and improvements; and have been communicated to all employees.

ANTI-CORRUPTION AND ANTI-BRIBERY

We are committed to creating a corporate culture to operate our businesses in an ethical manner while upholding the highest standards of professionalism.

As part of our continuous commitment towards creating a business environment built on transparency, integrity and free corruption, we have participated an en-bloc signing ceremony of the Malaysian Anti-Corruption Commission (“MACC”) Corruption Free Pledge on 2 July 2018 organised by the Federation of Malaysian Manufacturers (“FMM”).

This Corruption Free Pledge is a voluntary pledge to hold organisation and its leadership as well as each of its members accountable and responsible for carrying out their duties and to deter them from engaging in any corrupt misconduct throughout their tenure.

CONTRIBUTING TO THE INDUSTRY

We actively participate in industrial association activities to learn, develop and contribute towards best practices for the industries where we are involved in.

Below is a list of associations where our Group’s business divisions are members and / or active partners:

| Association |

|---|

|

ADVANCING IBS AND ENERGY EFFICIENT BUILDING SOLUTIONS THROUGH COLLABORATIONS

We work closely with various government bodies/agencies including but not limited to Construction Industry Development Board (“CIDB”) and Jabatan Kerja Raya (“JKR”) to drive the transformation of the construction industry in Malaysia especially on the adoption of IBS and energy efficient building solutions.

Our representatives are often part of the working groups to advance sustainability rating tools and industry standards in areas of IBS and energy efficiency in buildings to promote sustainable green building solutions among construction industry players in Malaysia.

Today, we are a ready supplier of components and integrated IBS, certified by CIDB. We are also granted by JKR as official system provider for pre-fabricated cold formed steel roof trusses in Malaysia. In addition, we are recognised by CIDB as “Pusat Latihan Bertauliah IBS” for lightweight steel framing system.

As a “Pusat Latihan Bertauliah IBS”, we leveraged the potential of the workforce among the youth in order to reduce dependency on foreign workers, while at the same time enhancing the skills levels of construction workers by organising workshops and trainings for contractors and students from polytechnics and universities to enhance their skill levels in lightweight steel framing system. Such activities are aligned with the vision of CIDB to produce more competent labour force that can be qualitative, productive and efficient at construction works.

COMMITMENT TO QUALITY TO ENSURE CUSTOMER SATISFACTION

We believe quality is key to ensuring customer satisfaction. Our metal roll-forming and safety glass products are manufactured under stringent quality management system and we have registered to obtain “Perakuan Permatuhan Standard” for products required under the CIDB Act 520.

Our Metal Division had been accredited by SIRIM the MS ISO 9002:1994 since 1996, updated to ISO 9001:2008 in 2009 and continued our quality commitment with the latest ISO 9001:2015 in 2017. In addition, our Metal Division has registered to obtain “Perakuan Permatuhan Standard” in 2018 for Self-supporting Steel Roofing.

Meanwhile, our Glass Division obtained BS EN ISO 9002:1994 accreditation in 1998, updated to ISO 9001:2000 in 2002, and ISO 9001:2008 in 2010. In 2016, we obtained Product Certification Licence for Tempered Safety Glass and Laminated Safety Glass in Building fully complying with MS1498:2011. In addition, our Glass Division has obtained “Perakuan Permatuhan Standard” in 2016 for Tempered Safety Glass and Laminated Safety Glass in Building.

PROMOTING GREEN BUILDING SOLUTIONS

Over the years, we have been working tirelessly together with authorities and professionals to develop more sustainable buildings in Malaysia. As one of the founders of Malaysia Green Building Confederation (“MGBC”), an organisation endorsed and supported by World Green Building Council (“WGBC”), we continue to spearhead the development of green building solutions for a sustainable built environment in Malaysia.

Our metal-roll forming products are able to substitute timber-based building materials, which in turn reduce logging activities, whereas our energy efficient and high performance safety glass products play a part in facilitating energy conservation through reducing energy consumption for cooling, as well as minimising noise, heat and UV rays.

As a sustainable green building solutions provider, our representatives are often invited to give public speeches to educate and create awareness about sustainable green building solutions. The public speeches/events where our Group’s representatives were invited during the year included:

| Speech / Event | Organiser |

|---|---|

|

The Institution of Engineers Malaysia |

|

Malaysia Green Building Confederation |

|

Trueventus |

|

CIDB Malaysia and Malaysia Green Building Confederation |

|

Malaysia Green Building Confederation |

ENERGY, WATER AND WASTE MANAGEMENT

We remain committed to preserving the environment by implementing environmental-friendly practices in our operations. We have taken conscious steps into improving our manufacturing processes and continuously worked towards reducing electricity and water consumption throughout the Group. We practice 5S activities throughout the Group and have scheduled audits for waste management.

In addition, one of our subsidiary, namely Asia Roofing Industries Sdn Bhd, has partnered with the Department of Environment Malaysia (“DOE”) in 2017 for the purposes of carrying out the conversion of factory facilities to enable the phase-out of hydro-chlorofluorocarbons (“HCFC”) to contribute to the national HCFC consumption and phase-out targets for Malaysia. The duration of such exercise is about 2 years and it is being carried out in five (5) stages:

(I) Implementation of work plan and plant re-layout;

(II) Procurement of equipment and service;

(III) Plant modifications;

(IV) Installation and commissioning of procured equipment; and

(V) Inspection by DOE and completion of HCFC phase-out.

As at 30 November 2018, we have completed the first 3 stages and currently carrying out Stage IV: installation and commission of the procured equipment for the above exercise.

At workplace, we encourage energy saving measures such as controlling the air conditioning temperature at reasonable level and turning off electrical appliances when no one is using. We practice recycling at our offices and reuse recycled papers whenever possible, to reduce paper usage.

CARING FOR COMMUNITIES

We care about giving back to the community. However, beyond pure philanthropy, we endeavour to deliver meaningful initiatives with lasting outcomes to a diverse group of beneficiaries.

During this financial year, we donated to various non-profit organisations including but not limited to Haemodialysis Centre, Resources & Education for Autistic Children, Tabung Thalassaemia Malaysia and Pertubuhan Membantu Pesakit Parah Miskin Malaysia to assist these organisations in their operating expenses and running of existing programmes.

PROVIDING GREATER ACCESS TO EDUCATION

We recognise that access to education is one of the key enablers in eradicating poverty. We aim to provide access to basic education and support the education needs of deserving students. As part of our commitment to empower and nurture these students, we have provided scholarships to them to further pursue their education at higher learning institutions.

Apart from scholarships, we work along with higher learning institutions such as Politeknik Port Dickson and Politeknik Melaka to offer internship programmes for their students. These internship programmes aim to provide the students practical exposure to real-world corporate considerations related to the fields of civil engineering and IBS that would benefit them upon graduation.

In addition, we give recognition to the children of our employees for achieving outstanding results in their academics as a gesture of encouragement to promote the emphasis on education.

PROMOTING SPORTS AND WELLBEING

Employee wellbeing has important implications for productivity and work relationships. To encourage wellbeing among the employees, we have our own sport clubs such as Ajiya Football Club, Ajiya Cycling Team, Y2K Club, R-Life Club and One Ajiya Club to provide ways for employees to join together, promote team building and encourage healthy lifestyle. Our employees also participated in annual community sport events such as TARCian Run, TARCian Unity Golf and Dato’ Theng Book Cup Malaysian Media Badminton Tournament.

HOSTING FACTORY VISITS FOR STUDENTS AND INDUSTRY ASSOCIATIONS

We organises educational visits for students from higher learning institutions and members from industry associations, introducing them technologies and innovations contributing to green buildings along with best practices on health, safety and environment, and thus inspiring them through practical exposure and knowledge.

In May 2018, we have organised a visit for CIDB Perlis and Persatuan Kontraktor Melayu Malaysia (“PKMM”) to our metal roll-forming and IBS manufacturing factory in Sungai Petani, Kedah, sharing our manufacturing process and advocating the use of IBS as part of the green building solution (better safety , more productive and higher quality construction works with minimal debris at site).

While in August 2018, we have arranged a visit for Persatuan Akitek Malaysia (“PAM”) to our safety glass processing factory in Puchong, Selangor, sharing our manufacturing process and advocating the use of energy efficient and high performance safety glass as part of the green building solution (facilitating energy conservation through reducing energy consumption for cooling, as well as minimising noise, heat and UV rays).

WORKFORCE

Our business success depends on our employees, who are our catalysts for excellence and innovation. We strive to provide our employees a safe, inclusive and conducive work environment that allows for personal and professional growth. As at 30 November 2018, we have a staff strength of 1080 employees group-wide.

DIVERSITY

Our policies and initiatives such as recruitment, retention, training and development as well as corporate and social activities are all implemented in a manner that does not discriminate against ethnicity, gender, age, disability or status. We employs, appoints, promotes, develops and rewards our employees through the principles of meritocracy and fairness, achieved through the implementation of an annual appraisal system. We are committed to hiring and promoting people based on company-defined criteria. Below are the statistics showing the diversity in our Group’s workforce as at 30 November 2018:

(i) Ethnic Diversity

- Malay

- Chinese

- Indian

- Others

(ii) Gender Diversity

- Female

- Male

(iii) Age Diversity

- < 30

- 30 - 40

- 41 - 50

- > 50

(iv) Women Workforce In Executive And Managerial Level

- Female

- Male

LEARNING AND CONTINUOUS IMPROVEMENT

We strive to develop a diverse pipeline of talents and give our employees opportunities to learn and grow, overcome challenges, take on new roles and adopt greater responsibilities. We know our current and prospective employees expect pathways to new opportunities that reward them for their performance value contributions. Offering our employees a challenging working environment that tests and builds their capabilities not only sets them up for success, it also makes our businesses stronger and more innovative.

For example, in July and October 2018, we have carried out several workshops for our top and middle management to train them on Theory of Inventive Problem Solving (“TRIZ”). TRIZ offers systematic innovation, where it is a toolkit to find ways of solving a problem, to find new concepts and routes for developing new products.

Our Ajiya CTRIZ team has participated the MyTRIZ Competition 2018 held on the last quarter of 2018 and won the first runner up. The competition was open to all including industry, academia and school. It was evaluated based on application of TRIZ tools to identify problem, originality and innovativeness of solution.

TALENT DEVELOPMENT AND SUCCESSION PLANNING

We focus on attracting and retaining talent and then helping them to develop their skills to drive our Group’s success. To this end, we are committed to bringing on board talent with the appropriate competencies as well as the relevant experience and qualifications. We provide continuous support by way of employee training and development and encourage them to take ownership of their personal growth. Other than serving the immediate needs of the Group, these efforts are helping us to establish a strong pool of talent and a pipeline of successors for the Group.

We have developed and implemented a competency framework across the Group to identify and outline specifically the required standards of knowledge, skills and behaviours required for successful job performance. The competency assessment serves to evaluate the competency levels of all employees as well as identify their competencies and skills gaps.

EFFECTIVE OCCUPATIONAL HEALTH AND SAFETY MEASURES

We have been practicing strict compliance to all safety, health and environmental requirements in relation to the Occupational Safety and Health Act as well as Environmental Quality Act. Each work location has its own Occupational Safety and Health Committees. The committees are tasked to organise and carry out various safety awareness, improvements and legally required training and activities such as basic firefighting, first aid competency course, safe chemical handling, chemical spill, emergency response, safety campaigns, quarterly safety inspections and committee meetings, and annual location for fire drills. All scheduled waste are recorded and stored before being disposed/recycled.

EMBRACING INNOVATION AND DIGITAL TRANSFORMATION

In this fast-paced business environment, we need to constantly innovate to stay competitive. We embarked on the journey towards digital transformation through the setup of our own roadmap. Through this roadmap, we are currently undertaking several initiatives to enhance our digital capability in the key areas of enterprise architecture, cyber security, governance and network infrastructure. We collaborate with external consultants and higher learning institutions to work on the projects under our digital transformation initiatives, combining the required expertise to work more effectively towards our digital transformation goals.